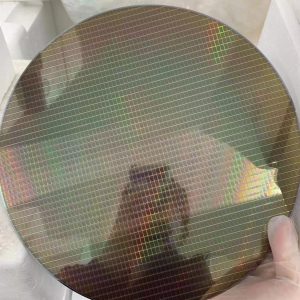

Polished wafer

UNIELECTRON&SIC can offer polished wafer, n type or p type with orientation at <100>, <110> or <111>. More Specifications, please see tables below.

Our advantages at a glance

- Advanced epitaxy growth equipment and test equipment.

- Offer the highest quality with low defect density and good surface roughness.

- Strong research team support and technology support for our customers

1. Specifications of Polished Silicon Wafers

1.1 FZ Polished Wafers Specifications

FZ polished silicon wafer: mainly for the production of silicon rectifier (SR), silicon controlled rectifier (SCR), Giant Transistor (GTR), thyristor (GRO)

| Type | Conduction type | Orientation | Diameter scope(mm) | Resistivity scope(Ω cm) | Geometric parameter graininess,surface metal |

| FZ | N&P | <100>&<111> | 76.2-200 | >1000 | T≥260(um) TTV≤2(um) TIR≤2(um) STIR≤1(um)(20*20) Graininess≤10pcs(≥0.3um) , ≤20pcs(≥ urface metal≤5E10/cm2 BSD:Etchpit density>1E106pcs/cm2 Poly:5000-12000 A |

| NTDFZ | N | <100>&<111> | 76.2-200 | 30-800 | |

| CFZ | N&P | <100>&<111> | 76.2-200 | 1-50 | |

| GDFZ | N&P | <100>&<111> | 76.2-200 | 0.001-300 |

1.2 CZ Polished Wafers Specifications

| Type | Conduction type | Orientation | Diameter scope(mm) | Resistivity scope(Ω cm) | Geometric parameter graininess,surface metal |

| MCZ | N&P | <100> <110>&<111> | 76.2-200 | 1-300 | T≥260(um) TTV≤2(um) TIR≤2(um) STIR≤1(um)(20*20) Graininess≤10pcs(≥0.3um) ,≤20pcs(≥0.2um) Surface metal≤5E10/cm2 BSD:Etchpit density>1E106pcs/cm2LTO:3500~8000±250A |

| CZ | N&P | <100> <110>&<111> | 76.2-200 | 1-300 | |

| MCZ heavily doped | N&P | <100>&<111> | 76.2-200 | 0.001-1 |

2. About Polished Wafer

High-purity electronic grade polysilicon undergoes the steps of crystal pulling, slicing, beveling, lapping, etching, polishing, and cleaning to produce a polished wafer, which meets electrical, surface physical properties, impurity standards and other specifications. Wafers with special processes such as annealing, epitaxy, and SOI are processed based on polished wafers.

Polished wafer (PW) is a silicon chip with atomic flatness that is single side or double sides polished silicon wafer, accounting for about 70% of silicon wafer applications. After the monocrystalline silicon ingot is produced, it is cut into thin slices from the cylindrical monocrystalline silicon of the ingot, which is a wafer of high-purity silicon element. The purpose of polishing is to further remove the residual damage layer on the processed surface. The polished monocrystalline silicon wafer can be directly used to fabricate devices or as an epitaxial substrate material. Polished Si wafer is widely used in digital and analog integrated circuits, memory, power devices and other chips.

N Type Sb Doped Silicon Wafer for Integrated Circuit Manufacturing

PAM XIAMEN offers MCZ silicon ingot and silicon wafer.

PAM XIAMEN offers black lithium Niobate wafers for optics and SAW Components

Stoichiometric LPCVD Nitride on Silicon Wafers

4″ Prime CZ Si wafer with one side sputtering Cr/Au layer thickness 10/50nm

Zero Diffraction Si Wafer Diameter 32mm for XRD measurements

Silicon Nitride Waveguide – Substrates and Services Provided

Super Low Stress Nitron on Silicon Wafers

Low Stress Nitride Silicon Wafers

Targeted Stress LPCVD Nitride

Silicon Wafers with (211) Orientation

Cleaving Silicon Wafers

Prime Grade Silicon Wafers

Silicon Wafer Properties

Silicon Wafers for Soft Lithography

Silicon Wafers PDMS Micro-Fluidic Chip Platforms

Ultra-Thinned Silicon Wafers

What are Silicon Wafer Flats?

N-Type Silicon Substrates

Float Zone Silicon Wafers

Undoped Silicon Wafers

P-type silicon substrates

Custom Silicon Wafers

Solar Silicon Wafers

PECVD Nitride

Lithium Niobate

Polished silicon slab

1″&1.5″ Silicon Wafer

125mm Silicon Wafer

150mm&200mm Silicon Wafer

25.4 (1 inch) Silicon Wafers

Porous Silicon Wafer

Silicon Ingots -1

Silicon Ingots -2

Silicon Wafer Thickness:275+- 25µm

Silicon Wafer Thickness:1000μm

2″ silicon wafers Thickness:1000 ±25μm

Si wafer Thickness: 675 ± 25 um

4″ Si wafer Thickness:500±20μm

3″ Si wafer Thickness: 380±20μm

50.8mm (2 Inch) Silicon Wafers-1

50.8mm (2 Inch) Silicon Wafers-2

50.8mm (2 Inch) Silicon Wafers-3

50.8mm (2 Inch) Silicon Wafers-4

50.8mm (2 Inch) Silicon Wafers-5

76.2mm (3 Inch) Silicon Wafers

100mm (4 Inch) Silicon Wafers-1

100mm (4 Inch) Silicon Wafers-2

100mm (4 Inch) Silicon Wafers-3

100mm (4 Inch) Silicon Wafers-4

100mm (4 Inch) Silicon Wafers-5

100mm (4 Inch) Silicon Wafers-6

125mm (5 Inch) Silicon Wafers

150mm (6 Inch) Silicon Wafers

200mm (8 Inch) Silicon Wafers

300mm Silicon Wafers

450mm Silicon Wafers

Diced Silicon Wafers

(111) Silicon Wafers

(110) Silicon Wafers

(100) Oriented Silicon Wafers-1

(100) Oriented Silicon Wafers-2

(100) Oriented Silicon Wafers-3

(100) Oriented Silicon Wafers-4

(100) Oriented Silicon Wafers-5

(112) Orientation Silicon Wafers

2″CZ Prime Silicon Wafer

2″CZ Prime Silicon Wafer-1

2″CZ Prime Silicon Wafer-2

2″CZ Prime Silicon Wafer-4

3″CZ Prime Silicon Wafer

3″CZ Prime Silicon Wafer-1

4″CZ Prime Silicon Wafer-6

4″CZ Prime Silicon Wafer-7

4″CZ Prime Silicon Wafer-8

4″CZ Prime Silicon Wafer-9

4″CZ Prime Silicon Wafer-10

4″CZ Prime Silicon Wafer-11

4″CZ Prime Silicon Wafer-12

4″CZ Prime Silicon Wafer-13

4″CZ Prime Silicon wafer-15

4″CZ Prime Silicon wafer-16

6″CZ Prime Silicon Wafer

6″CZ Prime Silicon Wafer-1

6″CZ Prime Silicon Wafer-2

6″CZ Prime Silicon Wafer-3

6″ CZ Si Wafer

8″CZ Prime Silicon Wafer

8″CZ Prime Silicon Wafer-1

8″CZ Prime Silicon Wafer-2

2″ FZ Intrinsic Silicon Wafer

2″ FZ Si wafer with SSP

4″ FZ Intrinsic Silicon Wafer SSP

4″ FZ Intrinsic Silicon Wafer DSP

4″FZ Prime Silicon Wafer-9

6″FZ Prime Silicon Wafer-2

6″FZ Prime Silicon Wafer-1

5″ FZ Silicon wafers

6″ FZ Silicon Wafer

6″FZ Silicon Wafer-1

6″ FZ Silicon Wafer-4

6″ FZ Silicon Wafer-7

6″ FZ Silicon Wafer-8

Silicon Ingots-1

Silicon Ingots-2

Silicon Ingots-3

Silicon Ingots-4

Silicon Ingots-5

Silicon Ingots-6

Silicon Ingots-7

Silicon Ingots-8

12″ Silicon Wafer

8″ Silicon Wafer

8″ Silicon Wafer-2

8″ Silicon Wafer-3

6″ Silicon Wafer-1

6″ Silicon Wafer-2

6″ Silicon Wafer-3

5″ Silicon Wafer

4″ Silicon Wafer-1

4″ Silicon Wafer-2

4″ Silicon Wafer-3

4″ Silicon Wafer-4

4″ Silicon Wafer-1

4″ Silicon Wafer-2

4″ Silicon Wafer-3

4″ Silicon Wafer-4

4″ Silicon Wafer-5

4″ Silicon Wafer-6

4″ Silicon Wafer-7

4″ Silicon Wafer-8

4″ Silicon Wafer-9

4″ Silicon Wafer-10

4″ Silicon Wafer-11

4″ Silicon Wafer-12

4″ Silicon Wafer-13

4″ Silicon Wafer-14

4″ Silicon Wafer-15

4″ Silicon Wafer-16

4″ Silicon Wafer-17

4″ Silicon Wafer-18

3″ Silicon Wafer-1

3″ Silicon Wafer-2

3″ Silicon Wafer-3

3″ Silicon Wafer-4

3″ Silicon Wafer-1

3″ Silicon Wafer-2

3″ Silicon Wafer-3

3″ Silicon Wafer-4

3″ Silicon Wafer-5

3″ Silicon Wafer-6

3″ Silicon Wafer-7

3″ Silicon Wafer-8

3″ Silicon Wafer-9

3″ Silicon Wafer-10

3″ Silicon Wafer-11

3″ Silicon Wafer-12

3″ Silicon Wafer-13

3″ Silicon Wafer-14

3″ Silicon Wafer-15

3″ Silicon Wafer-16

3″ Silicon Wafer-17

3″ Silicon Wafer-18

3″ Silicon Wafer-19

3″ Silicon Wafer-20

3″ Silicon Wafer-21

2″ Silicon Wafer-1

2″ Silicon Wafer-1

2″ Silicon Wafer-2

2″ Silicon Wafer-3

2″ Silicon Wafer-4

2″ Silicon Wafer-1

2″ Silicon Wafer-2

2″ Silicon Wafer-3

2″ Silicon Wafer-4

2″ Silicon Wafer-5

2″ Silicon Wafer-6

2″ Silicon Wafer-7

2″ Silicon Wafer-8

2″ Silicon Wafer-9

2″ Silicon Wafer-10

2″ Silicon Wafer-11

2″ Silicon Wafer-12

2″ Silicon Wafer-13

2″ Silicon Wafer-14

2″ Silicon Wafer-15

1″ silicon wafers

2″ Silicon Oxide Wafer

3″ Silicon Oxide Wafer

4″ Silicon Oxide Wafer

4″ FZ N type Si wafer

Polycrystalline Back Sealed Polished Wafer